box and Packaging

5 layer carton

Cartons are made in different sizes and types with different thicknesses. 5 layer cartons include poultry cartons, industrial cartons, crafts cartons, crockery, cosmetics dividers, and more. Five-layer cartons in the food and beverage, cosmetics, N and F micro-flutes are the type of materials that are capable of printing and are still harder to use than E-FLUT.

The question here is what is E-FLUT and are flutes suitable for carton printing? E-flute is not suitable for direct Offset Printing and requires printing on a separate sheet and then laminating.

The use of five-layer carton is diverse and not limited. But 5 layer carton is stronger than 3 layer carton. The difference between this carton and the three-layer carton is its strength. 5-layer cartons are more durable than 2-layer cartons because of 2 layers.

Many people ask what size 5-layer cartons are made? The answer is that 5-layer carton is usually made in the following dimensions:

33 * 33 * 33 or (book box)

33 * 30 * 43

40 * 42 * 46

60 * 46 * 46

60 * 46 * 6

The dimensions you want can be customized and changed.

Featured of 5-layer carton:

- Flexibility in holding heavy and large objects

- Different shapes and sizes

- Weight bearing from 20 to 45 kg

- High durability

- Convenient space

- Suitable price

- Suitable for moving and storing large objects

- Suitable moving

- Suitable for making large cartons

How to make 5 layer carton?

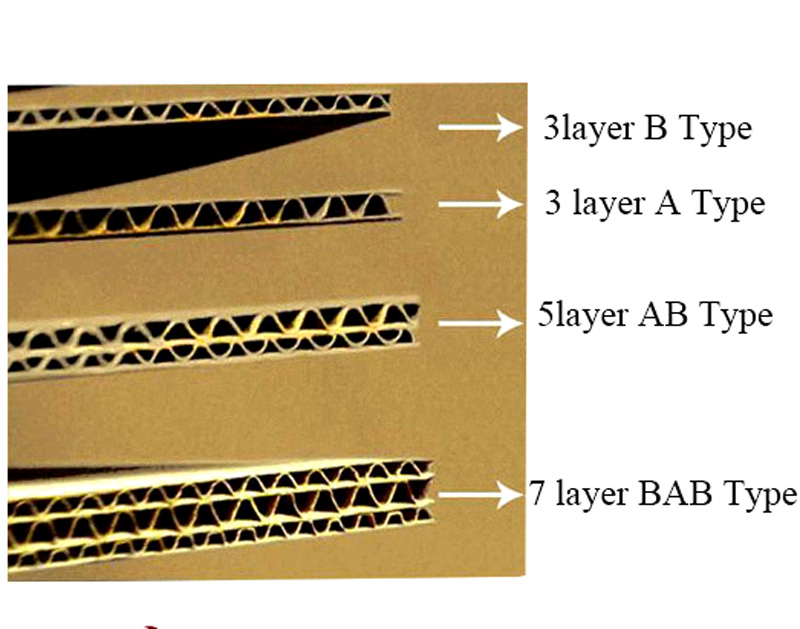

Step 1: To make a 5-layer carton, just use 3 flat and 2 flute layers.

Step 2: Put the liner and flute sheets together with glue. How layers are arranged, such as the rule of b + c, b + e, c + e or e + e waves.

Step 3: Perform a five-layer carton quality control test to check the carton's resistance to pressure to determine the maximum weight the carton can carry and calculate the maximum layer strength.

This test is crucial for the production of cardboard boxes because they can be made using cartons that are less expensive to manufacture. The cardboard box is placed between the two plates and the pressure is applied until the plates are bent. Then this pressure is calculated. This is important for determining the types of pressures on different levels of the cardboard box during shipping.

Step 4: Put the cardboard on the water for a limited time. Note that weight gain reflects water absorption by the cardboard. Water permeability is important because water and any moisture can adversely affect the strength of the box.