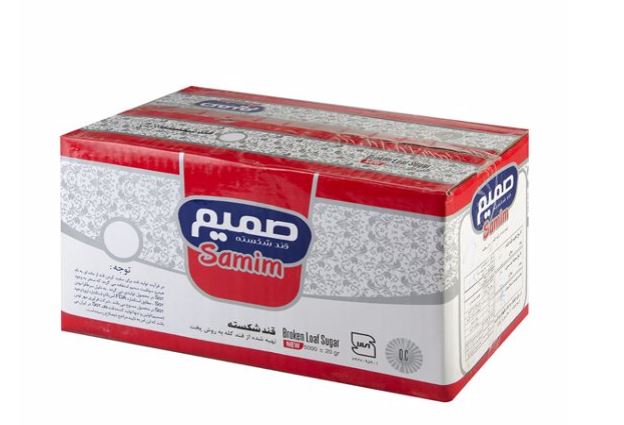

box and Packaging

Carton with printing

Printing custom designs is one of the needs of many business owners today.

Production and printing of a carton involves the following steps:

Step One: Design

Step Two: Sample Construction

Step Three: Stereotype construction

Step Four: Mold construction

Step Five: Producing the sheet and transfer it to the printing machine

Step 6: Printing and finishing operations such as varnish, slitter, die cut, glue or punching, folding, packing, shearing.

To see more samples click here.

The box is designed depending on product type and the importance of precision in box dimensions is for two reasons: First, good storage and secondly, good carton alignment, the major box designs include the following:

- Full Door Head (FOL)

- Half carton box (HSC)

- Tubes

- Complete Door Secret Box (OLSC)

- Full telescopic projection

- mattress (tray)

- Die cut boxes

There are many factors involved in designing a carton. The most important of these can be stated as:

-

- Keep the product in a good place so that the packaging itself and its content are not damaged due to impact and displacement.

- Easy to carry.

- Maximum carton alignment.

- Suitable for the manufactured goods.

- Its design represents the product within it.

- The body color of the paper is proportional to the product inside it.

- Packaging cartons are resistant to temperature changes.

- If it depends on the main consumer, the color will identify the product inside.

- Sample making

After the design is ready and approved, the design CD is sent for making example, and the sample developer produces the custom design on carton by sample making machine.

- Stereotyping

Stereotyping is one of the pre-printing operations in the carton industry, which can be called an important fate in print because if the layout is not designed and the stereotyping is not realized, we will not get the desired print.

- Observe the necessary points before stereotyping

Make sure that no damage is done to the films while loading the films. Because if our film is right where the tram is, there will be a break in our film and the stereotype will be damaged and we will have trouble printing.

Another point to keep in mind is that the salty stereo device and the vacuum device cover should be clean. That is, the water or substances we use to wash the stereotype.

Another important precaution we need to take is the correct use of the raw stereo, which is approximately 1 or 2 mm from the film side. Most importantly, our raw stereotype should not be open because if it sees the light then the stereotype is no longer usable.

Die cut cartons are processed by blade molds and are without dimension tolerance. The use of die cut cartons in the carton industry includes:

- Hollow carton: Includes fruit cartons and cartons of seafood and dairy products. (Dairy cartons in the carton industry are also called refrigerated cartons)

- Telescopic carton: Includes banana carton

- Split carton: Includes carton for metal parts

- One door carton: Includes product display cartons

- Carton without door: Includes stove, refrigerator and household utensils

Similar articles

# Carton with staple connection

# Cardboard box with glue connection