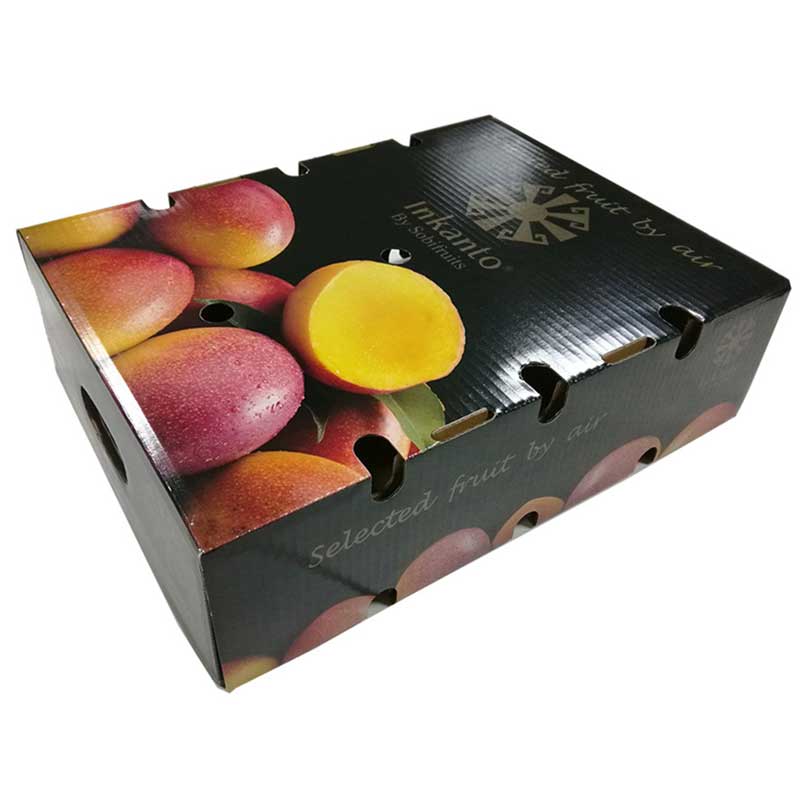

box and Packaging

Carton with pores

Some products, especially agricultural products, require cartons that are easy to pack and have pores so that air can be easily get in and get out.

Consider, for example, that the fruit is a cooling process that reduces the temperature of fruits and vegetables to a certain temperature in the shortest possible maturity after harvest and before storage or shipment. The main purpose of this process is to reduce the rate of biochemical, microbiological, respiratory and enzymatic reactions and other changes to prevent product spoilage, maintain quality and extend its shelf life.

Consider, for example, that the fruit is a cooling process that reduces the temperature of fruits and vegetables to a certain temperature in the shortest possible maturity after harvest and before storage or shipment. The main purpose of this process is to reduce the rate of biochemical, microbiological, respiratory and enzymatic reactions and other changes to prevent product spoilage, maintain quality and extend its life. Cartons with lower pore maturity have lower cooling and more uniform air distribution in the box. The increase in airflow also results in subtraction of cooling time in the whole boxes. Therefore, cartons should be made that do not spoil or destroy the materials in the carton.

Carton paper industry is divided into two parts: 1- Liner paper, 2- Medium paper.

Liner paper that is applied to the cardboard layers without any deformation and should be even from strengthened and impervious fibers. Medium-sized, conglomerate-based paper is durable, made of long, soft fibers, and has the flexibility to maintain this shape. There are, of course, many divisions about wrapping paper in terms of quality, type of appearance, and grammar (base weight) that are always used.

In the Single-facer section, the beginning of the conglomerate-mediated, corrugated roll of medium-sized paper is rolled out immediately (by the Applicator Roll adhesive cylinder) and cross-linked to the liner paper and processed into a double-layered or modified (Single- face) cardboard. This processed cardboard then adheres to its complementary double-backer, and thus adheres to another liner paper and processes a body sheet.

The main segmentation of cardboard produced by the type of congress is the manufacturer of that sheet. Because, as mentioned, the main endurance of the carton is provided by conferences or the so-called craft flotation.

Part Two or Transformations:

The task of the conversion unit is to convert the cardboard sheets into cardboard. Basically every

The carton is divided into two groups from the perspective of shape.

- Simple cartons with cube form divided into three categories.

A. Normal carton

B - Half carton (large cartons used for wrappers)

c - Door, body or telescopic cartons (such as fruit cartons)

- Cartons that are complex in form and often used for aesthetics and for delicate orders, these cartoons are put into the work of another (motherboard).

The so-called die-casting carton is the basic design of the work on the mold. This mold is mechanically constrained to lay the necessary design on the carton sheet and not to create the corresponding cutting and tie lines.

Similar Articles

# Carton with staple connection